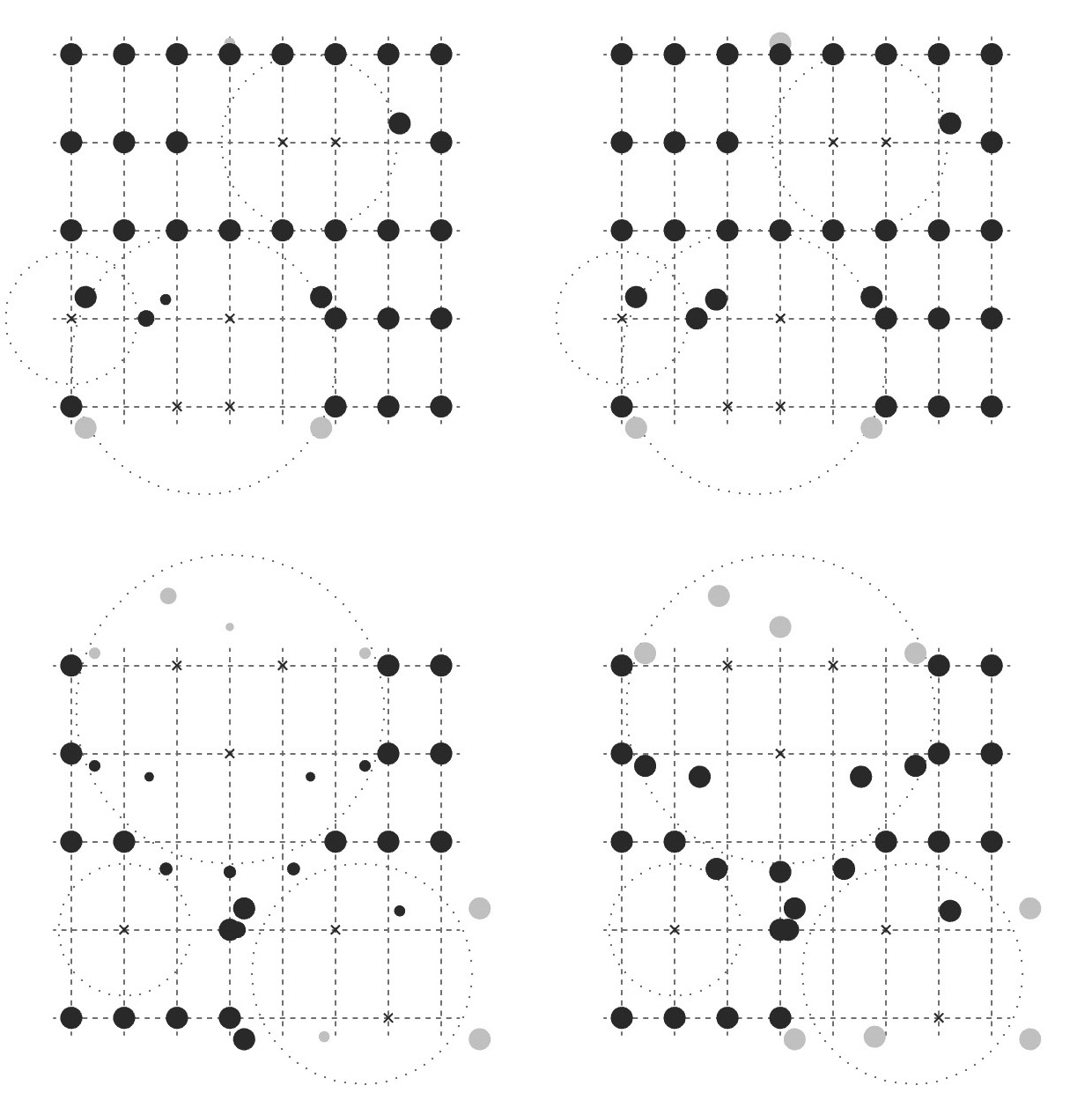

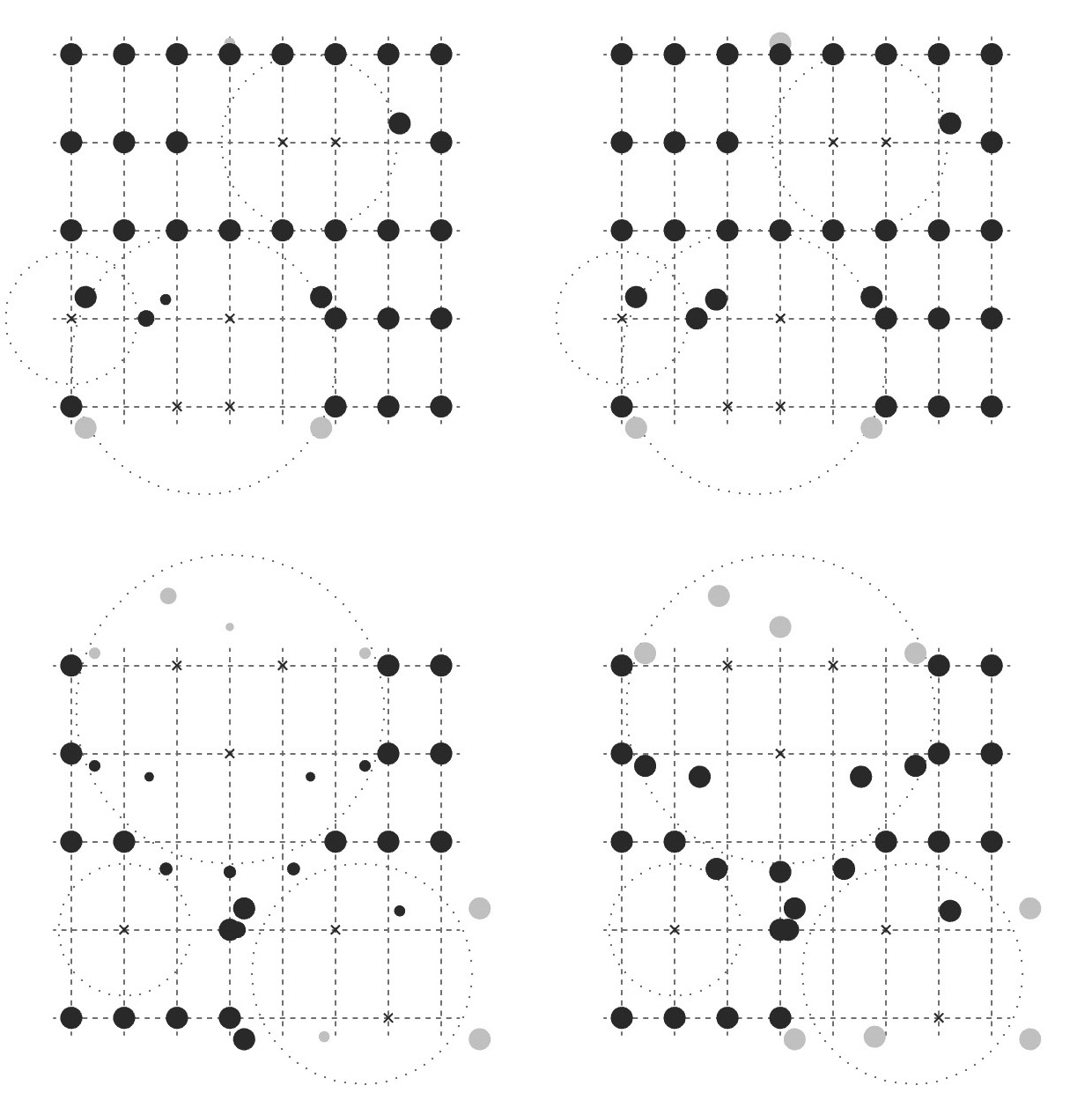

Planting Patterns

The MASS Haptic Pavilion follows traditional planting patterns in managed pine plantations across the Southeastern U.S.

Southern Yellow Pine forests are highly organized, with specific spacing producing specific tree densities. The diagrams below represent 500- and 650-trees per acre densities. As the forest matures, tree density can be reduced by factors including climate, insects, disease, and animal interactions.

Working forests start as a grid of seedlings, with the expectation that approximately 15% of the stand will die before harvest. As the stand suffers tree loss, gaps (“rooms”) amongst the forest are exposed. The MASS Haptic Pavilion incorporates these natural gaps, which serve as spaces for visitors to gather.

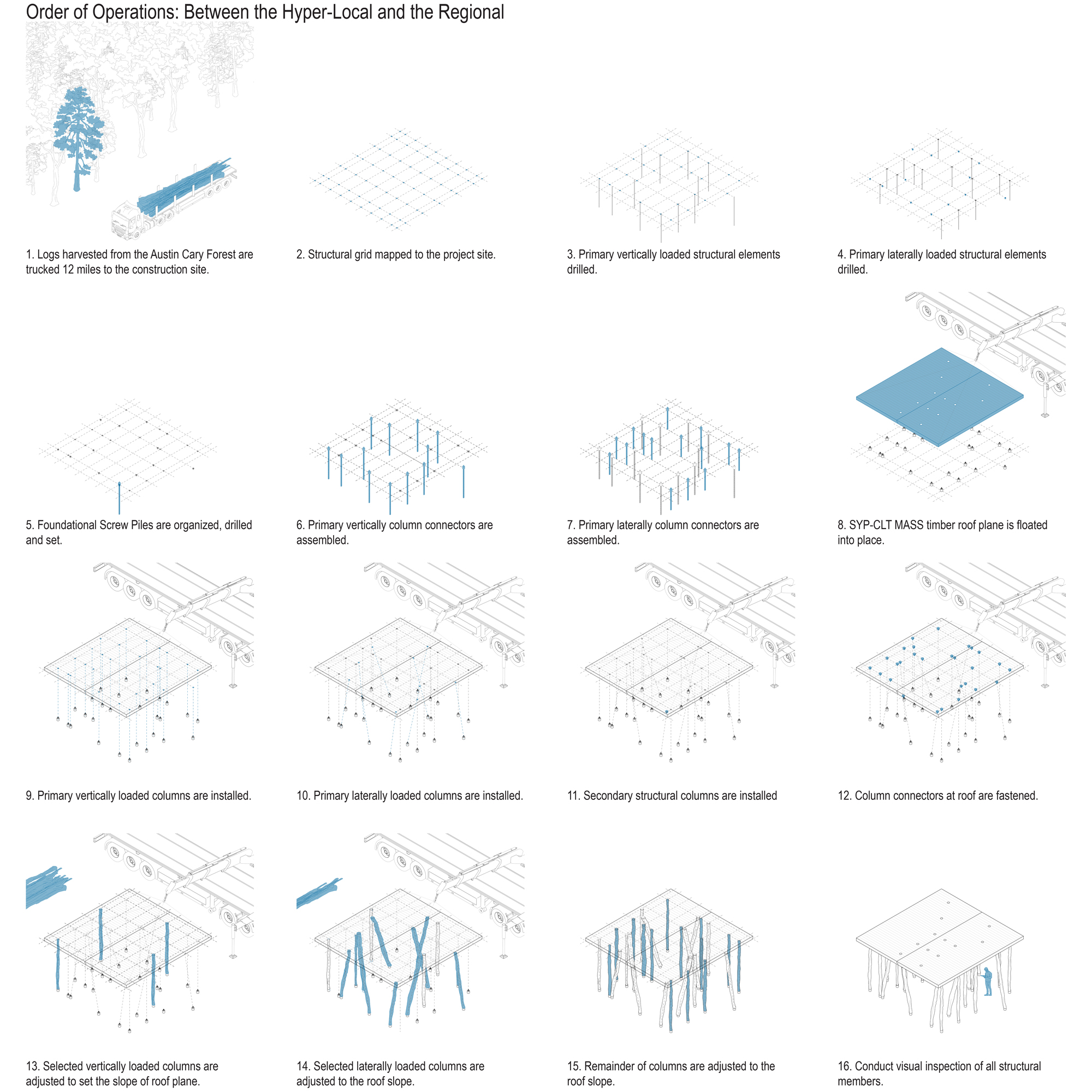

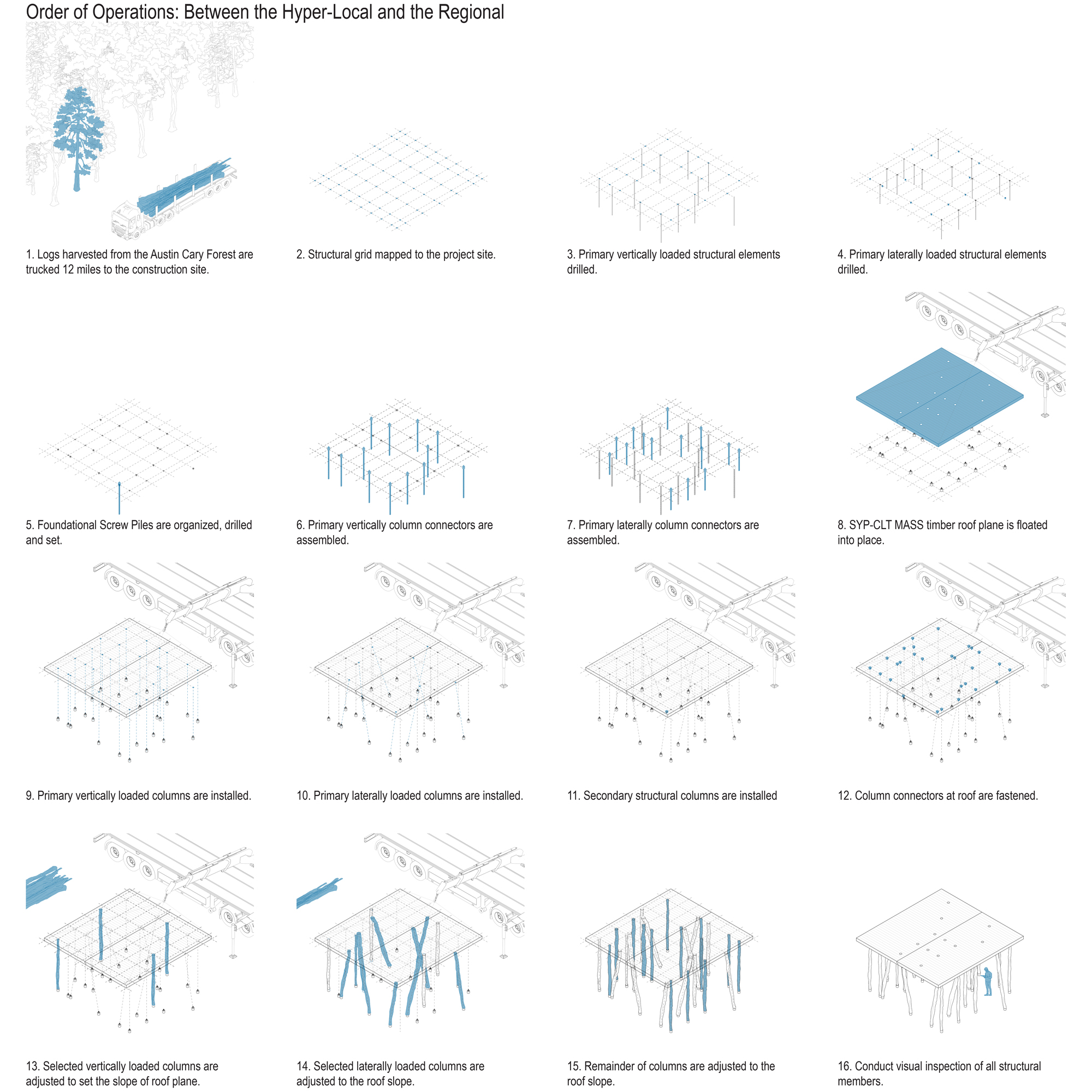

Construction/Assembly Process

MASS Haptic was assembled over two days. The first day included the installation of the foundation system and columns. On the second day, roof panels were craned into place.

The roof canopy is constructed from Cross-Laminated Timber (CLT) panels, created from standard-sized lumber fused together using modern fabrication methods. These panels were produced at the SmartLAM plant in Dothan, Alabama, from trees harvested and milled in Florida, Georgia, and Alabama.

Poles made from whole logs support the roof panels and invoke the variability of the forest from which wood is harvested. These columns were grown at the University of Florida’s own Austin Cary Forest, before being transported to this project site.

Image 1.

Image 2.

Image 3.

Image 4.

The structural elements for MASS Haptic were harvested from the University of Florida’s Austin Cary Forest. This forest is an actively-managed, 2,600-acre property dominated by Southern Yellow Pine. A three-dimensional scan of a 100’ by 200’ section of forest provided a “Material Supply.” Lesser-grade trees were kept whole and used in their log forms as structural members.

Learn more about University of Florida’s Austin Cary Forest here.